Last update: January 28, 2021

| P/N | Appearance | Qty | Material | Remarks | Applicable model Links | Applicable models |

|---|---|---|---|---|---|---|

|

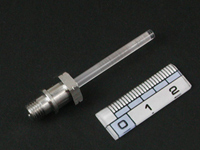

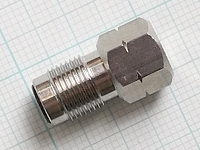

228-52069-44

|

|

1 | Sapphire | With diaphragm |

40DXR 40DXS 40DX3 40BXR 40BX3 |

|

|

228-35009-93

|

|

1 | Sapphire | → External view |

20AT 20Ai optional for 10ATvp |

|

|

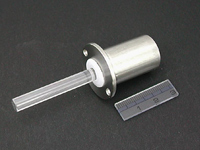

228-20284-91

|

|

1 | Sapphire | 228-17019-93 with holder → External view |

20AR 6AD |

|

|

228-17019-83

|

|

3 | Sapphire | → External view |

20AR 6AD |

|

|

228-17019-93

|

|

1 | Sapphire | → External view |

20AR 6AD |

|

|

228-32654-92

|

|

1 | Zirconia | With a holder *1) → External view |

optional for 10Ai |

|

|

228-32654-91

|

|

1 | Sapphire | With a holder *1) → External view |

10Ai |

|

|

228-35009-92

|

|

1 | Zirconia | *2) → External view |

10ATvp |

|

|

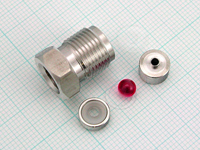

228-35281-91

|

|

1 | Zirconia | 228-35601-91 with holder and O-ring. *2) → External view |

10ADvp |

|

|

228-70428-41

|

|

1 | Sapphire |

Mikros |

||

|

228-35601-91

|

|

1 | Zirconia | *2) → External view |

10ADvp |

|

|

228-35601-93

|

|

1 | Sapphire | → External view |

30ADSF 20AB 20AD 20ADXR 20ADSP 20ADnano 2010 2010HT optional for 10ADvp |

|

|

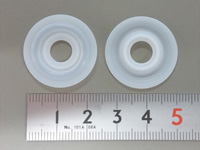

228-35281-95

|

|

1 | Sapphire | 228-35601-93 with holder → External view |

30ADSF 20AB 20AD 20ADXR 20ADSP 20ADnano 2010 2010HT optional for 10ADvp |

|

|

228-51269-41

|

|

1 | Sapphire | → External view |

20AP |

|

|

228-52069-94

|

|

1 | Sapphire | With diaphragm → External view |

30AD |

|

|

228-35281-97

|

|

1 | Sapphire | With diaphragm → External view |

2040 2030 |

|

|

228-16837-91

|

|

1 | Sapphire | With a holder *1) → External view |

8A |

*1) This plunger has a plunger fixing holder as an integrated part and is finely adjusted. A plunger assembly is not provided as a single part.

*2) The color of the current plunger is white. Plungers provided up to April 2002 were cream-colored and ones provided up to July 1998 were white.

Changing a material of a plunger seal may increase the service life depending on the type of the mobile phase used.

Changing a material of a plunger seal may increase the service life depending on the type of the mobile phase used. When changing a material of a seal, seats and other parts are also necessary.

For details, click here.

■ Material Indication

GFP, GF: Reinforced PTFE (PTFE including additives), PE: UHMWPE (Ultrahigh molecular weight polyethylene)

| P/N | Appearance | Qty | Material | Remarks | Applicable model Links | Applicable models |

|---|---|---|---|---|---|---|

|

228-52711-93

|

|

1 | PE | with Backup Ring |

40DXR 40DXS 40DX3 40BXR 40BX3 30AD 2040 Plus Mikros |

|

|

228-51266

|

|

1 | GFP |

20AP |

||

|

228-35146

|

|

1 | GFP |

2030 2010 2010HT 20AD 20AB 20ADVP 20ADnano opitional for 2040 |

||

|

228-35146-84

|

|

3 | GFP |

2030 2010 2010HT 20AD 20AB 20ADVP 20ADnano opitional for 2040 |

||

|

228-35145

|

|

1 | GFP |

20AT 10ATVP |

||

|

228-35145-84

|

|

3 | GFP |

20AT 10ATVP |

||

|

228-32628-91

|

|

1 | PE |

2040 30ADSF 20ADnano 20ADXR 20ADSP optional for 2030 optional for 2010 optional for 2010HT |

||

|

228-21975-91

|

|

1 | PE |

20AR 20Ai 10Ai 6AD optional for 10ATVP |

||

|

228-21975-84

|

|

3 | PE |

20AR 20Ai 10Ai 6AD optional for 10ATVP |

||

|

228-18092

|

|

1 | GF |

8A |

||

|

228-18092-84

|

|

3 | GF |

8A |

Notes for Changing a Material of a Plunger Seal

When changing a material of a plunger seal, parts other than the seal are also necessary.

See the details below.

| Seal Material | Other Than LC-10AT/LC-10ATVP | LC-10AT/LC-10ATVP |

|---|---|---|

| GFP→PE GF→PE |

PE seal kit (P/N 228-33233-91) A set including the following parts

|

Two types of seats (P/N 228-32325-01 and 228-32401) For the LC-10ATVP, the rinsing seal also needs to be changed. →Rinsing seal for the LC-10ATVP |

| PE→GFP | GFP seal kit (P/N 228-35349-91) A set including the following parts

|

Seal cap (P/N 228-35804)*2) |

*2) For early LC-10ATVP models, P/N 228-35147 (metallic) was used. Currently 228-35804 (trifluoroethylene) is used.

Rinsing Seal of the LC-10ATVP

When changing a material of a plunger seal from GFP to PE or changing the rinsing seal for the LC-10ATVP manufactured in June 1998 or earlier to the current seal, the rinsing seal and mounting parts for it also need to be changed.

When Changing a Material of a Plunger Seal from GFP to PE

When changing a plunger seal with one made of PE, the rinsing seal and mounting parts for it also need to be changed. The following additional parts are necessary.

- Rinsing seal P/N 228-28499

- Seal holder P/N 228-35816-91

- Ring holder P/N 228-39109-01

When Changing the Rinsing Seal Used on the LC-10ATVP Manufactured in June 1998 or Earlier to the Current One

When changing the rinsing seal to the current one (P/N 228-35145), the holder also needs to be changed. Use the P/N 228-35946-91 seal holder assembly (with a seal).

| P/N | Appearance | Qty | Remarks | Applicable model Links | Applicable models |

|---|---|---|---|---|---|

|

228-56200-48

|

|

1 | Assembly (stainless steel) |

40BX3 |

|

|

228-70356-41

|

|

1 | Assembly (stainless steel) |

Mikros |

|

|

228-56200-49

|

|

1 | Assembly (stainless steel) |

2040 2040 Plus 2030 2030 Plus |

|

|

228-48118-91

|

|

1 | Assembly (stainless steel) |

20ADnano |

|

|

228-45708-91

|

|

1 | Assembly (stainless steel) |

30ADSF 30AD 2030 2040 2010 2010HT 20ADXR 20ADnano 20AR 20AD 20AB 20AT 6AD optional for 10ADVP optional for 10ATVP |

|

|

228-39181-94

|

|

1 | Assembly (ceramic) |

20ADSP 20Ai 10Ai |

|

|

228-25079-91

|

|

1 | Ceramic filter main unit |

20Ai 10Ai optional for 20AD optional for 10AB optional for 20AT optional for 10ADVP optional for 10ATVP |

|

|

228-20031

|

|

1 | Filter main unit, ESKA-P5375C (stainless steel) |

20AP 8A |

|

|

228-18740-95

|

|

1 | PE |

optional for 20Ai |

|

|

228-17421-91

|

|

1 | Assembly (stainless steel) |

8A |

|

|

228-17421-42

|

|

1 |

20AP |

On the assembly, the filter main unit (stainless steel or ceramic), tube, coil spring, ferrule, bush, and other parts are mounted.

| P/N | Appearance | Qty | Remarks | Applicable model Links | Applicable models |

|---|---|---|---|---|---|

|

228-57501-92

|

|

1 |

40DXS 40DX3 40BX3 |

||

|

228-70394-42

|

|

1 |

Mikros |

||

|

228-58173-42

|

|

1 | with Certificate of Materials |

30ADSF |

|

|

228-35871-99

|

|

1 |

30AD |

||

|

228-35871-96

|

|

1 | Housing, integrated with a stainless steel filter |

2030 2040 2010 2010HT 20ADXR 20ADnano 20AR 20AD 20AB 20AT optional for 10ADVP *2) optional for 10ATVP *2) |

|

|

228-39082-91

|

|

1 | Line filter, housing |

10ADVP 10ATVP |

|

|

228-48607-91

|

|

1 | PEEK frit |

20ADSP 20Ai 10ADVP *2) 10ATVP *2) 10Ai *2) optional for 20AD *1) optional for 20AB *1) optional for 20AT *1) |

|

|

228-48607-92

|

|

5 | PEEK frit |

20ADSP 20Ai 10ADVP *2) 10ATVP *2) 10Ai *2) optional for 20AD *1) optional for 20AB *1) optional for 20AT *1) |

|

|

228-33265

|

|

1 | Line filter, housing |

20Ai 10Ai |

|

|

228-12642-93

|

|

1 | Line filter assembly Packing (P/N: 228-12564) is neccessary when replaced. |

6AD |

|

|

228-12642-84

|

|

5 | Line filter assembly Packing (P/N: 228-12564) is neccessary when replaced. |

6AD |

|

|

228-18405-91

|

|

1 | Line filter (with packing) |

20AP 8A |

*1) Former standard accessories for the LC-20AD/AB/AT

*2) On the LC-10ADvp/10ATvp, 228-35871-96 is easier to handle than 228-48607-91.

■ Material of the Check Valve

Unless the material is described in Remarks, the cartridge is made of stainless steel, the ball is made of ruby, and the seat is made of sapphire.

| Name | P/N | Appearance | Qty | Remarks | Applicable model Links | Applicable models |

|---|---|---|---|---|---|---|

| Check Valve IN |

228-52964-42

|

|

1 |

40DXS 40DX3 40BX3 |

||

| Check Valve IN |

228-39093-84

|

|

3 |

10ADVP |

||

| Check Valve IN |

228-20256-91

|

|

1 | →Exploded view |

8A |

|

| Check Valve IN |

228-61830-41

|

|

1 | The cartridge is made of PEEK. |

20Ai 10Ai |

|

| Check Valve IN |

228-35721-81

|

|

3 | The ball and seat are ceramic →Exploded view. |

optional for 10ATVP *1) |

|

| Check Valve IN |

228-35721-91

|

|

1 | The ball and seat are ceramic →Exploded view. |

optional for 10ATVP *1) |

|

| Check Valve IN |

228-32166-84

|

|

3 | →Exploded view |

10ATVP |

|

| Check Valve IN |

228-32166-91

|

|

1 | →Exploded view |

10ATVP |

|

| Check Valve IN |

228-35719-82

|

|

3 | The ball and seat are ceramic. |

optional for 20AD optional for 20ADXR optional for 20AB optional for 20ADSP optional for 20ADnano optional for 20AT |

|

| Check Valve IN |

228-35719-92

|

|

1 | The ball and seat are ceramic. |

optional for 20AD optional for 20ADXR optional for 20AB optional for 20ADSP optional for 20ADnano optional for 20AT |

|

| Check Valve IN |

228-39093-92

|

|

1 | →Exploded view |

10ADVP |

|

| Check Valve IN |

228-70308-41

|

|

1 | Primary Check valve cartridge |

Mikros |

|

| Check Valve IN |

228-37149-92

|

|

1 | Check valve cartridge, DIV →Exploded view |

2010 2010HT |

|

| Check Valve IN |

228-48249-42

|

|

1 | In the case of the LC-20AT: Lefy side when viewed from the front Reference: Illustration of LC-20AT Flow Line →Exploded view |

20AT |

|

| Check Valve IN |

228-20283-91

|

|

1 | →Exploded view |

20AR 6AD |

|

| Check Valve IN |

228-50950-41

|

|

1 | →Exploded view |

20AP |

|

| Check Valve IN |

228-52964-95

|

|

1 | →Exploded view |

30AD |

|

| Check Valve IN |

228-48249-97

|

|

2 | →Exploded view |

40D 40DXR 40BXR 2030 2040 20AD 20ADXR 20AB 20ADSP 20ADnano |

|

| Check Valve IN |

228-48249-96

|

|

1 | →Exploded view |

40D 40DXR 40BXR 2030 2030 Plus 2040 2040 Plus 20AD 20ADXR 20AB 20ADSP 20ADnano |

|

| Check Valve IN |

228-48249-41

|

|

1 | with Certificate of Material |

30ADSF |

|

| Check Valve IN |

228-70374-41

|

|

1 | Secondary Check valve |

Mikros |

|

| Check Valve IN |

228-20256-84

|

|

3 | →Exploded view |

8A |

|

| Check Valve OUT |

228-45705-43

|

|

1 |

40D 40DXR 40BXR |

||

| Check Valve OUT |

228-45705-41

|

|

1 | with Certificate of Meterial |

30ADSF |

|

| Check Valve OUT |

228-53334-96

|

|

1 | →Exploded view |

40D 40DXR 40BXR 30AD |

|

| Check Valve OUT |

228-45705-91

|

|

1 | →Exploded view |

2030 2040 20AB 20AD 20ADXR 20ADSP 20ADnano optional for 10ADVP *2) optional for 10ATVP *2) |

|

| Check Valve OUT |

228-50955-41

|

|

1 | →Exploded view |

20AP |

|

| Check Valve OUT |

228-37147-93

|

|

1 | →Exploded view |

2010 2010HT |

|

| Check Valve OUT |

228-34976-91

|

|

1 | →Exploded view |

10ADVP 10ATVP |

|

| Check Valve OUT |

228-34976-81

|

|

3 | →Exploded view |

10ADVP 10ATVP |

|

| Check Valve OUT |

228-32798-91

|

|

1 | The cartridge is made of PEEK. |

20Ai |

|

| Check Valve OUT |

228-32798-84

|

|

3 | →Exploded view |

10Ai |

|

| Check Valve OUT |

228-09054-93

|

|

1 | →Exploded view |

20AR 8A |

|

| Check Valve OUT |

228-09054-84

|

|

3 |

6AD |

*1) If acetonitrile (100 % and other high concentrations) is left, a heavy dirt may remain inside the check valve, causing a malfunction. This check valve can operate smoothly even under such circumstances. When using this valve, check the flowrate. The flowrate may need to be corrected.

*2) When using on the 10ADvp/10ATvp, check the flowrate. Correct the flowrate if necessary.

Rinsing the Check Valve

Check valve tends to get dirty easily as solvents go through them. When using a check valve for a long period of time, it is recommended to rinse the valve regularly. Rinse the check valve when the operation of the instrument is stopped after analysis is finished, on weekends, or during a long no operation period.

■ Rinsing Procedures

- Prepare a reservoir bottle containing 2-propanol (approx. 200 mL).

- Connect a resistance tube (inner diameter 0.1 mm, 2 m long) to the outlet of the solvent delivery pump.

- Replace the mobile phase with 2-propanol by for example using the solvent delivery pump's purge operation.

- Set the flowrate so that the pressure is at least 10 MPa (standard: 1 mL/min).

- Deliver 2-propanol for at least 30 minutes.

Flowrate Correction

On the 20A/VP series, users can correct the flowrate using the VP function.

Measure the flowrate at the flowrate to be corrected and set the value for [FLOW COMP.FACT] on the [Calibration] menu of the VP function. For details, refer to the "Calibration Support Group" section of the instruction manual.

| Name | P/N | Appearance | Qty | Remarks | Applicable model Links | Applicable models |

|---|---|---|---|---|---|---|

|

228-55272-41

|

|

2 |

40D 40DXR 40DXS 40DX3 40BXR 40BX3 30AD 2030 2040 2040 Plus |

|||

|

228-32784-91

|

|

2 | White, PTFE (polytetrafluoroethylene), more solvent-tolerant and mechanically stronger than 228-24311-01 |

30ADSF 20AB 20AD 20ADXR 20ADSP 20ADnano 2010 2010HT 10ADVP |

||

|

228-24311-01

|

|

1 | Black, Viton® (fluoroelastomer), low solvent-tolerant *1) |

usable for 10ADVP |

||

|

228-24311-84

|

|

10 | Black, Viton® (fluoroelastomer), low solvent-tolerant *1) |

usable for 10ADVP |

||

|

228-51263

|

|

1 |

20AP |

|||

|

228-35935

|

|

1 | Polyethylene, white (translucent) *2) |

20AT 20Ai 10ATVP |

||

|

228-28499

|

|

1 | Polyethylene, white *2) |

10Ai |

||

|

228-28499-84

|

|

3 | Polyethylene, white *2) |

10Ai |

||

|

228-18306

|

|

1 | PTFE (polytetrafluoroethylene), gray |

8A |

||

|

228-18306-84

|

|

5 | PTFE (polytetrafluoroethylene), gray |

8A |

||

|

228-20282

|

|

1 | PTFE (polytetrafluoroethylene), gray |

20AR 6AD |

||

|

228-20282-84

|

|

1 | PTFE (polytetrafluoroethylene), gray |

20AR 6AD |

||

| Rising Seal |

228-70323-41

|

|

1 |

Mikros |

*1) Viton®is a registered trademark of DuPont Dow Elastomers Japan.

*2) On the LC-10ATvp units manufactured in June 1998 and later, the rinsing seal 228-35935 is used. On units manufactured earlier and ones with a polyethylene plunger seal, the rinsing seal 228-28499 is used. When changing the seal to a different type, the seal holder assembly also needs to be changed. (Details)

Supplementary keywords: Plunger, pump, HPLC, high-performance, ion chromatograph, preparative, inert, LC-30A, LC-20A, LC-10A, LC-2010, LC-2030, LC-2040, Prominence, Nexera, Seal, plunger, graphite, Bal, ion, LC-6A, LC-9A, LC-8A, GFP, PE, Suction filter, ion, preparative pump, inert pump, ceramic filter, Solvent delivery unit, LC-10ADvp, LC-10ATvp, LC-10Ai, LC-10AS, LC-10AD, LC-10AT, LC-6AD, LC-2010A, LC-2010C, line filter, Backflow, check valve, ball, seat, check, active inlet valve, LC-7A, rinsing, diaphragm, LC-40D, LC-40DXR, LC-40XS, LC-40DX3, LC-40BXR, LC-40BX3, LC-20AD, LC-20AB, LC-20ADXR, LC-20ADSP, LC-20ADnano, LC-20AT, LC-20Ai, LC-20AR, LC-20AP