How to Choose Integrating Spheres and White Reference Plates

When using an integrating sphere, measurement values can vary depending on the inner wall material of the integrating sphere and the white reference plate.

Therefore, this chapter describes some actual examples and discusses how to choose the inner wall material of the integrating sphere and the white reference plate.

1. Inner Wall Material of the Integrating Sphere

For diffuse transmitted light and diffuse reflected light measurements, a coating or plastic material with almost 100 % reflectance is used on the inner walls of integrating spheres. Primarily either barium sulfate paint ("BaSO4 paint" below) or a special fluoropolymer are used for these materials.

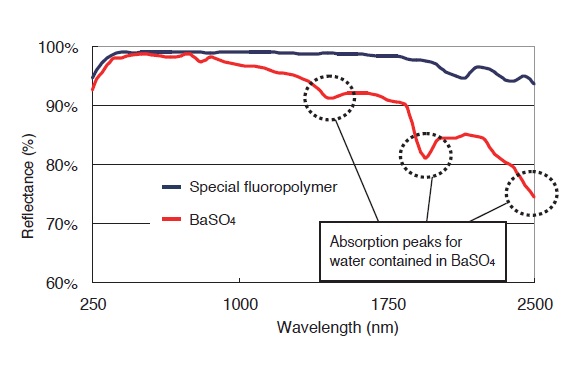

Fig. 1 shows the absolute reflectance of BaSO4 paint and a special fluoropolymer. The reflectance of these materials differs significantly in the near infrared region. For BaSO4 paint, reflectance in the visible light region is over 90 %, but drops to about 80 % in the near infrared region. In contrast, the reflectance for the special fluoropolymer is over 95 % in the visible light region and over 90 % even in the near infrared region.

Therefore, if only using the integrating sphere for measurements in the visible light region, then BaSO4 paint should provide more than adequate performance, but an integrating sphere with a special fluoropolymer interior would be more useful if performing precision measurements in the near infrared region.

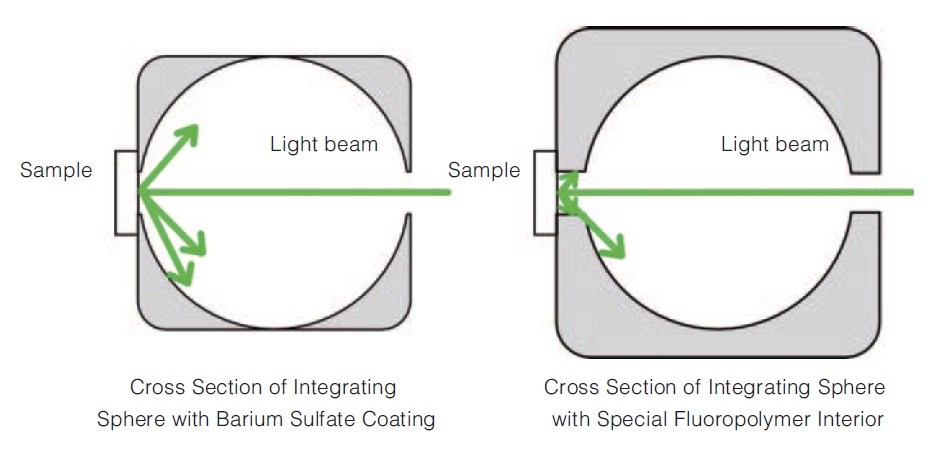

However, the problem with using the special fluoropolymer is that the interior wall thickness needs to be 8 to 9 mm to obtain adequate reflectance levels. This forms a ledge where the sample meets the integrating sphere’s inner wall, as shown in Fig. 2, which can affect measurements.

Note that the downward peaks in the BaSO4 spectrum in Fig. 1 near 1450 nm, 1950 nm, and 2500 nm are due to the absorption by water contained in BaSO4.

Fig. 1 Reflectance of Barium Sulfate Paint and Special Fluoropolymer

Fig. 2 Differences in Inner Wall Status Due to Differences in Integrating Sphere Material

2. White Reference Plate Materials

Typically, the material used for white reference plates is BaSO4 powder that has been pressed into a solid, but special fluoropolymer material is used for measurements that require high sensitivity in the near infrared region. Characteristics and procurement sources for the BaSO4 powder and special fluoropolymer are listed in Table 1. The following describes differences between the materials and how to use them.

Table 1 Comparison of White Reference Plates

| BaSO4Powder | Special Fluoropolymer | |

| Price | Low price (a few thousand yen per bottle) | About 100,000 yen per white reference plate |

| Reflectance Characteristics |

Lower reflectance in the near infrared region and includes absorption peaks from water | High reflectance characteristics throughout a wide range, from UV to NIR regions |

| Attachment of Absolute Reflectance Data |

Absolute reflectance data is not included with products, so measurement values cannot be converted to absolute reflectance values. | Absolute reflectance data is included with products, so relative reflectance values can be converted to absolute reflectance values. ※1 |

| Maintenance | Refill if BaSO4 becomes dirty | If the properties of the plastic change, the original reflectance values can no longer be obtained, so the reflective surfaces must be re-polished or replaced. |

| Representative Products |

Generic BaSO4 powder reagent | Spectralon™ from Labsphere ※2 |

※2 Spectralon™ is a registered trademark for a special fluoropolymer manufactured by Labsphere.

3. Effect of White Reference Plates on Reflectance Measurements

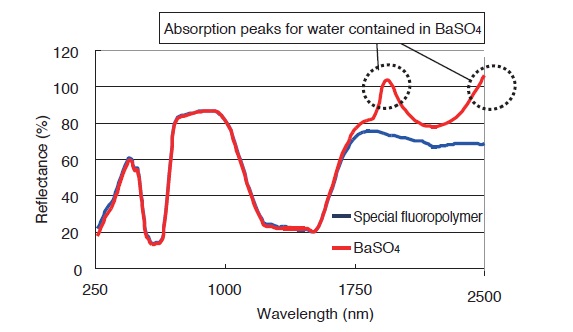

Reflectance measurements using an integrating sphere are relative reflectance measurements. Therefore, if the white reference plate changes, it changes the measurement values as well. To indicate such changes, reflectance measurement values are compared using tracing paper as a diffuse reflection sample and using BaSO4 and special fluoropolymer as the white reference plate. These results are shown in Fig. 3. The results confirm that the measurement values differ and the difference in measurement values is particularly prominent in the near infrared region, where the difference in reflectance from the white reference plate is especially large.

Fig. 3 Measurement of Tracing Paper Reflectance

Using Different White Reference Plates

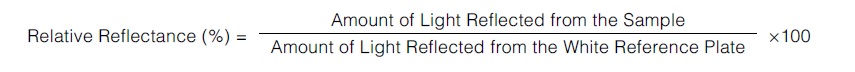

Relative reflectance is expressed by the following formula, which gives values that are affected by the reflectance of the white reference plate.

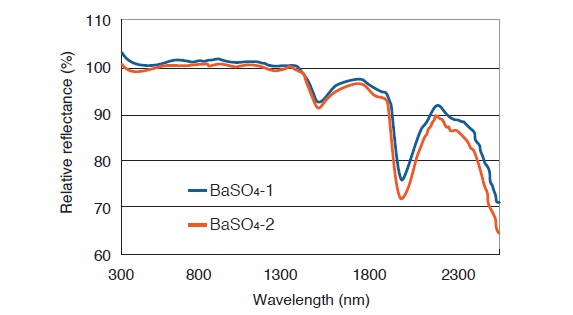

Fig. 4 shows results for measuring relative reflectance of two BaSO4 powder products used as white reference plates using a special fluoropolymer as the white reference plate. This indicates that differences in reflectance values can even occur for the same BaSO4 powder, due to how the powder was packed. Similarly, reflectance values can change for an identical white reference plate if the reflection surface becomes contaminated or deteriorates over time.

Fig. 4 Measurement of Reflectance

Using Two BaSO4 White Reference Plates

4. Relative Total Reflectance Measurement

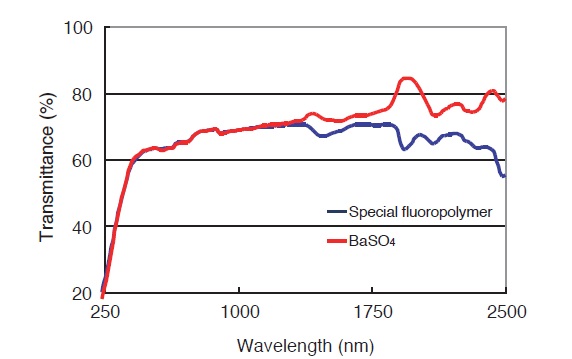

For clear samples that do not diffuse transmitted light, transmittance measurements determine the absolute transmittance. However, if measuring samples with some cloudiness that diffuses transmitted light, deviation from the absolute transmittance can be quite significant if the materials used for the inner walls of the integrating sphere and white reference plate differ. Therefore, it is necessary to use material in the integrating sphere and white reference plate that is as similar as possible. Fig. 5 shows total transmittance spectra (sum of diffuse and linear transmittance) for tracing paper as the diffuse transmittance sample measured using BaSO4 and a special fluoropolymer as the white reference plate material on the reflection surfaces inside the integrating sphere. It shows how differences in the white reference plate result in differences in spectra from a diffuse transmittance sample.

Fig. 5 Transmittance of Diffuse Sample with Different White Reference Plates

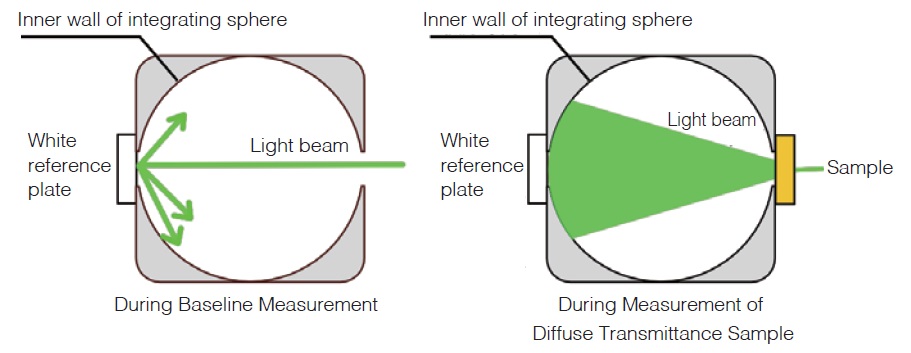

The causes of these differences in transmittance is detailed in Fig. 6. During baseline correction, the light beam travels straight so that the entire beam hits the white reference plate surface. In contrast, the light beam transmitted through the diffuse transmittance sample is diffused and hits a wide area inside the integrating sphere. Consequently, differences in reflectance levels of the white reference plate and the integrating sphere wall are included in measurement values and prevent obtaining absolute transmittance values.

Fig. 6 Status of Light During Measurement of Diffuse Transmittance Sample

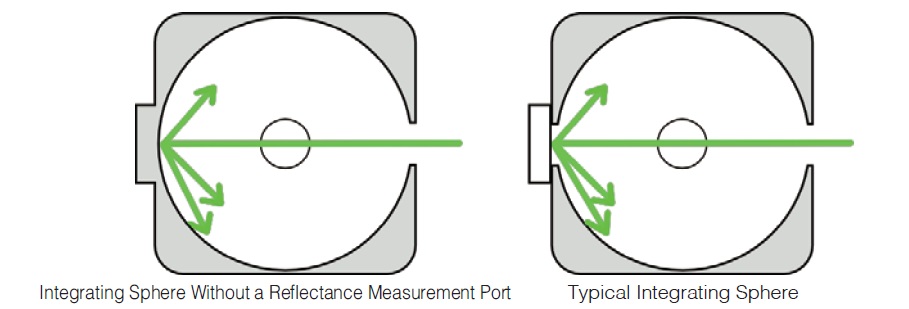

Typically, integrating spheres include a port for measuring reflected light on the opposite side of the sphere as the port for incident light, so that they can measure both transmittance and reflectance. However, to prevent differences when measuring diffuse transmittance samples, integrating sphere models are also available without the port for reflection (hole where the white reference plate is installed), as shown in Fig. 7.

Fig. 7 An Integrating Sphere Without a Reflectance Measurement Port and a Typical Integrating Sphere

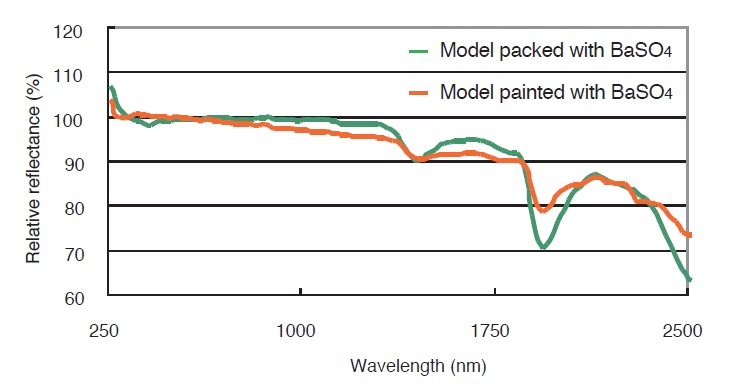

Furthermore, reflectance differs slightly even between models using packed BaSO4 powder and models painted with BaSO4. Fig. 8 shows an example of the difference in reflectance for these two types of reference plates. Therefore, to measure transmittance with higher precision, we recommend using an integrating sphere without the reflectance measurement port.

Fig. 8 Differences in Reflectance for Models Packed with BaSO4 Powder and Painted with BaSO4

5. Summary

This issue discusses characteristics of reflectance and transmittance measured using an integrating sphere and factors that can cause a margin of error in those measurements.

An important point to consider when measuring reflectance using an integrating sphere is that sample reflectance values are relative values compared to the reflectance of a white reference plate. Therefore, they can vary depending on variations in the material and status of the white reference plate.

If unexpected reflectance values are obtained from a sample that is the same as usually measured, then double-check that the white reference plate is not dirty or has somehow changed.

Also, if measuring the diffuse transmittance of a sample with high diffusion levels, using an integrating sphere model without a reflectance measurement port is recommended.