Measurement of High-Concentration Samples

In wet measurement of particle size distribution using the laser diffraction/scattering method as the principle of measurement (i.e., in wet measurement using a laser diffraction particle size analyzer) the appropriate sample concentration is said to be around 100 ppm, and measurement targets containing high-concentration particle groups, such as creams, paints and pastes, normally must unavoidably be diluted to measure their particle size distribution.

Yet, with high-concentration measurement targets such as these, it is feared that dilution will change the particle size distribution. Thus, there is a deep-rooted need for particle size measurement with the sample in its original state, that is, without it being diluted. This need spreads to a wide range of fields such as medicines and pharmaceuticals, cosmetics, chemical products, foods, and paints and pigments.

In measurement by the laser diffraction/scattering method, particles are irradiated with a parallel laser beam, and the spatial light intensity distribution pattern of the diffracted/scattered light emitted from these particles is used to specify the particle size. This method utilizes the property by which the light intensity distribution pattern changes in a 1:1 relationship dependent on particle size. As an assumption, the diffracted/scattered light emitted from particles must be detected by the sensor without irradiating other particles. To satisfy this assumption, in most cases, the measurement target must be diluted to keep the concentration of the particle group low.

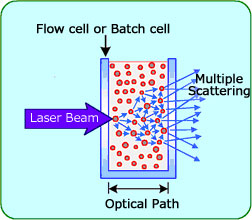

If a regular flow cell or batch cell is used to measure samples having a high particle group concentration, the optical path is long as shown in Fig. 1. So, diffracted/scattered light that is once emitted from the particles irradiates again other particles, and new diffracted/scattered light is emitted. This phenomenon, called "multiple scattering," is further repeated. When multiple scattering occurs, the laser beam irradiating almost all of the particles is no longer a parallel beam, the 1:1 relationship between particle size and light intensity distribution pattern ceases to be established, and the particle size can no longer be specified accurately. This multiple scattering has been regarded as the major reason for preventing high-concentration samples from being measured by the laser diffraction/scattering method.

Fig. 1 Example of High-Concentration Sample Measured by Regular Method

However, as shown in Fig. 2, the adverse influence of multiple scattering can be sufficiently averted by shortening the light path as much as possible by inserting the measurement target that contains the high-concentration particle group between two glass plates (glass slides). This is the basic way of thinking behind high-concentration sample measurement using the laser diffraction/scattering method.

If all conditions are met, even fairly high-concentration samples of 10% to 20% can be measured without the need for dilution, excluding some cases where they need to be diluted to an extent that will not adversely affect measurement.

Also, with respect to the distribution width, samples having a width relatively narrower than samples having a broad width are more suited to the measurement of high concentrations.

Fig. 2 Example of High-Concentration Sample Inserted Between 2 Glass Slides